Juliette Aymon

Looking at the greenhouse gas emission in Switzerland, it happens that the major emitters are industries and Waste-to-Energy (WtE) plants, which are responsible for about 7 Mt of CO2 release per year. Hence, if Switzerland want to reach the net zero carbon footprint in year 2050, these pollution sources can not be ignored. Various engineering sectors such as the ETH Zürich SUS.lab approach this problem by applying the carbon capture to WtE plants. [2] Looking at the global waste management, it appears that the energy recovery from waste is not the only greenhouse gas (GHG) emitter among the waste management sector. For that reason, other measures are necessary in order to minimize GHG emissions, which would supplement end-of-pipe technologies. Since plastic is nowadays a big concern and caused about 407 million tonnes waste in 2015, one cannot ignore the role of this synthetic material in climate change [1]. Therefore, it is also important to understand how this waste is managed and why some issues such as plastic recycling and bioplastic are not enough in order to reduce plastic waste.

Plastic – an omnipresent material

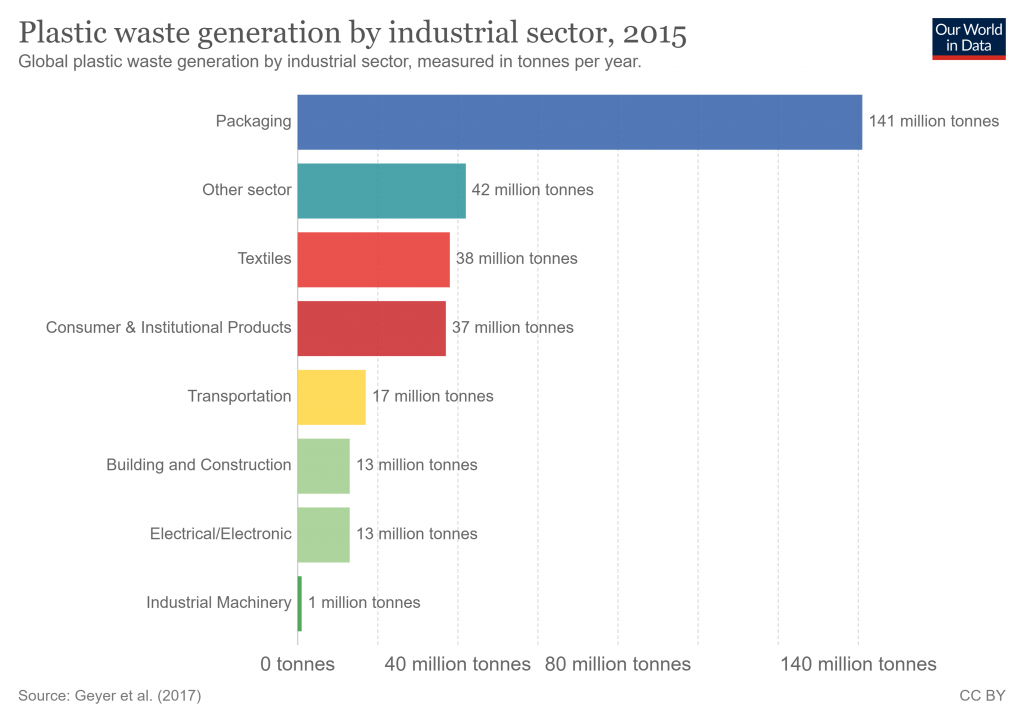

After the second world war, when the chemical industry developed new kinds of plastic such as the polyethylene terephthalate (PET), polyethylene (PE), polypropylene (PP), polystyrene (PS) and polyvinyl chloride (PVC), this polyvalent material began to play a major role in society. Plastic could be produced at low costs, was malleable, was the “material of a thousand uses” and because it allowed conservation of goods, it became a synonym for safe and sanitary. Since then, its uses have continually expanded. Today, this synthetic material can be found in almost every daily good.[3] Packaging represents the primary sector using plastic, since it consumed 146 M tones per year in 2015. Other sectors that also contribute to the high demand on plastic are building and construction (65 M tones), textiles (47 M tones), consumer and institutional products (42 M tones), transportation (27 M tones), electrical/electronic (18 M tones), industrial machinery (3 M tones) and other sectors (59 M tones). Because packaging, mostly for “single-use”, causes almost half of the total plastic waste, 302 M tones out of 407 M tones of plastic produced in 2015 were discarded. Because of its very short lifetime, packaging contributed to 47% of the total plastic waste in 2015. [1]

Figure 47.1 – Plastic waste generation by industrial sector, 2015

Plastic – a symbol of a linear economy

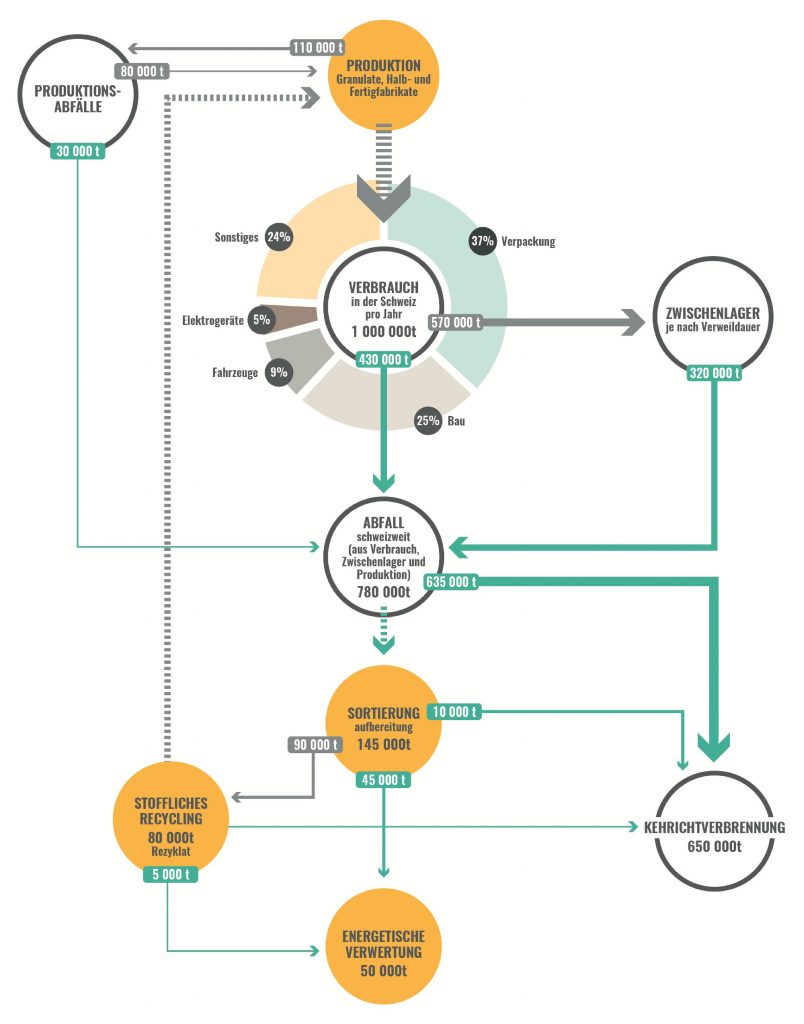

The philosophy of “produce – use – throw away”, which is the basis of the linear economy, leads to enormous amounts of waste, that humans cannot get rid of. Packaging plastic, which represents 47% of the plastic waste, symbolizes this philosophy perfectly. It is produced, used once and finally thrown away. Nowadays, waste management includes various methods. [3] In Switzerland for instance, from the annual 780’000 tonnes of waste produced, 650’000 tonnes are incinerated, 80’000 tonnes are recycled (material recovery) and 50’000 tonnes are combusted in order to produce energy (energy recovery or waste-to-energy). Whereas Switzerland does not landfill its combustible waste since 2000 anymore, this waste management method is still common and widely spread around the world. [4] However, waste management through landfill causes environmental and health hazards, since materials that are piled up in these sites are releasing toxins and gases.[5] Indeed, plastic that ends up in landfills leads to methane emissions, whose global warming potential is 21 times higher than CO2 over 100 years. [3] [6] Considering the impact of waste management on climate change and global warming landfills are particularly harmful.

Figure 47.2 – Plastic waste streams in Switzerland [10]

Waste management in Switzerland

The federal Office for the Environment (FOEN) noted that swiss plastic consumption is still increasing and reached 1 M tones per year in 2010. 78% of it became waste, 80% of which were used for energy recovery in WtE plants, 6% for cement industry and only 10% were recycled. Among the large variety of kinds of plastic, only two of them are recycled: PET and PE. If plastic is to be recycled, it has to have some specific properties. For instance, plastics should not be too dirty, for it would require a lot of energy, water and detergents to clean them. Economic and technical factors also determine whether the kind of plastic is suitable for material recovery or not. [4] Furthermore, although PET-bottles are collected separately, which increases their likelihood for recycling, in Europe, only 30% of them are eventually recycled. [3]

The fact is that the recycling process causes some material and quality loss. Of the total plastic packaging waste, only 14% is intended for recycling. Of these 14%, 4% of the material is lost, 8% will become another product with lower value and only 2% is converted into a similarly valuable product (for example PET bottle will become a new PET bottle). [3] The recycled outcome of plastic material is also generally less valuable, which means that it leads to products, that are not suitable for material recovery. Therefore, in many countries (but not in Switzerland), plastic ends up in landfill, anyway, where it releases methane. [3]

Bioplastics vs. biodegradable plastic

An alternative to the usual plastic made of petroleum is bioplastic, more precisely bio-based plastic, which is produced from biological resources such as sugar cane. The term of “bioplastic” can easily lead to confusion since it is commonly associated with “biodegradable plastic” or with “compostable plastic”. [3] However, the three terms have very distinct significations. “Biodegradable” means that the material is intended to be broken down by microorganisms. No time frame is given for this process. On the other hand, “compostable” means that the material degrades naturally through the activity of microorganisms, within a particular time frame. [7]

Generally, biodegradable plastics require industrial conditions in order to be degraded, where light, heat, oxygen and humidity are artificially set up. [8] The properties of the most common biodegradable plastic, polylactide (PLA), for instance, were investigated. After one year in the environment, PLA does not seem to have been degraded at all. Its total decomposition will probably take many more years. Finally, the misuse of the word “biodegradable” or the lack of explanation for this term leads to confusion in people’s minds. One can then easily think that these plastics will be broken down in their own compost, which is not the case. Admittedly, bioplastics have shown higher degradation rates in landfills, but air pollution through methane emissions remains. [3] [9]

If we consider the use of natural resources, bioplastic is for sure an interesting, more sustainable alternative, for it is made of renewable resources and its production emits less GHG. However, bioplastic cannot replace all the actual petroleum-based plastic, since it would require about 150 million hectares of land, which would then not be available as agricultural land for food production anymore. [3]

To summarize, some positive aspects concerning the plastic production and waste can be noticed. In Switzerland landfills are banned from the waste management system for combustible waste. Bio-based plastics have been developed, which preserve the natural resources and reduce the GHG emissions. However, bioplastics represented only 1% of the total plastic production in 2017 [8]. Biodegradable plastics represent a good alternative if they follow a biological waste treatment (i.e. composting and anaerobic digestion under controlled process conditions). However, all these alternative forms of basic (i.e. neither biobased nor biodegradable) petroleum-based plastics still cause a lot of waste, since the major part of it is incinerated, combusted in WtE plants or landfilled. For these reasons, the investigation of alternatives from different sectors in order to try to mitigate the impact of plastic is fundamental; at the level of consumption and waste management as well as recycling possibilities.

References:

[1] https://ourworldindata.org/plastic-pollution

[2] Eckle, P. (2020). Week 7// 1 April 2020: Climate Change, Decarbonization and Sustainable Industry [pdf]. Retrieved from https://moodle-app2.let.ethz.ch/course/view.php?id=11879

[3] Rhodes, C. J. (2019). Solving the plastic problem: From cradle to grave, to reincarnation. Science Progress, 102(3), 218-248. doi:10.1177/0036850419867204

[4] https://www.bafu.admin.ch/bafu/en/home/topics/waste/guide-to-waste-a-z/plastics.html

[5] https://www.plasticsrecyclers.eu/challenges-and-opportunities

[6] https://unfccc.int/process/transparency-and-reporting/greenhouse-gas-data/greenhouse-gas-data-unfccc/global-warming-potentials

[7] https://www.bpiworld.org/Composting

[8] Rujnic-Sokele, M., & Pilipovic, A. (2017). Challenges and opportunities of biodegradable plastics: A mini review. Waste Management & Research, 35(2), 132-140. doi:10.1177/0734242×16683272

[9] Gironi, F., & Piemonte, V. (2011). Bioplastics and Petroleum-based Plastics: Strengths and Weaknesses. Energy Sources Part a-Recovery Utilization and Environmental Effects, 33(21), 1949-1959. doi:10.1080/15567030903436830

[10] https://www.bafu.admin.ch/bafu/en/home/suche.html#plastic%20waste