Clara Gund

By 2050 oceans are expected to contain more plastics than fish. Every year, up to 13 million tonnes of plastic reach the ocean, which is equivalent to dumping the contents of one garbage truck into the ocean every minute, according to UN Environment [1]. In recent years companies have made it their goal to find a way to use these extremely valuable, raw materials plastic waste proposes and transform the plastics economy by turning plastic waste back into oil. However, there are still many obstacles which need to be faced in order to make this process a revolutionary transformation in the next decade.

Why should we transition to a new plastics economy?

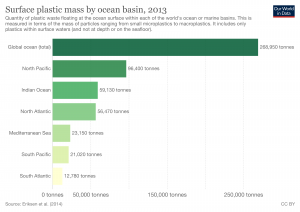

On the ocean’s surface lies the Great Pacific Garbage Patch, a floating cluster of plastic covering an estimated 1.6 million square kilometres, an area three times the size of France [1]. Globally only 18% of plastic is recycled, the rest will end up in landfills and oceans and will take up many decades to decompose [2]. Plastic waste in the environment will cause harm to natural ecosystems, specifically many animal species below and above water surface, as well as many populations and communities living in poverty.

Figure 1: Surface plastic mass in the oceans of the world [3].

Today’s plastic consumption and pollution are inarguably one of the biggest challenges and will play a big role in decarbonisation processes and shifting away from fossil fuel dependence. The current fossil fuel based industry is neither durable nor sustainable and is in desperate need of a transformation. However banning plastic altogether and switching to a plastic-free society is not only an unrealistic goal for the majority of the world, but also would demand a shift backwards instead of onwards. Plastic substances are an enormously important resource of this century, which only very few non-plastic-alternatives could potentially substitute. Some of our most valued institutions such as medical and experimental science infrastructure strongly rely on plastics. Therefore, re-establishing the value of plastic waste as a high-energy carbon source or as base materials for the plastic industry will be crucial in transforming the plastics economy from linear to circular, while maintaining the ability not to neglect heavily plastic-reliable institutions and thus ensuring the welfare of society.

Innovation: Using waste plastics to make crude oil

ReOil, a pilot research project from the company OMV in Austria have made it their mission to close the gap in the plastic industry by converting used plastics back into oil. Estimates suggest that it could become a $50-billion-a-year business within this decade. The idea of the process is simple in theory, but a little more complicated upon further investigation and when bringing practicality into the picture. Plastic is created from crude oil and therefore can be transformed back into its components. To achieve the transformation however, plastic waste has to be heated over 400°C under moderate pressure for long periods of time to disrupt the long-chain molecules [4]. The endproduct is synthetic crude oil, which can then be used as refinery feedstock to produce fuels or as base materials for the plastics industry, which makes it a resource-efficient circular process.

Given that plastic polymers are very poor conductors of heat, the plastic used for these processes has to be of high quality standards, which only few waste products meet. These include typical PET bottles and other plastics such as packaging foils or containers made from thick-walled polyethylene or polypropylene. Despite all these challenges, OMV has built a ReOil unit that can recycle up to 100kg of plastic into 100 litres of synthetic crude oil per hour and aims to hit one more scale-up stage of 2000kg per hour processing level in the coming years, before reaching final industrial-scale capacity.

Figure 2: Suitable plastic types for the ReOil conversion process [5].

Will this method bring revolutionary change?

While ReOil will not completely solve the problem of the Great Pacific Garbage Patch and landfills we have today, it could offer a chance in increasing the sustainability of many plastic producing industries tomorrow.

If the quality of current disposed waste plastic could be improved to fit the standards used to turn them back into oil, ReOil seems like a promising trajectory to a circular economy of the plastics industries. The path to get there however will not happen overnight. The transition will require companies to change to reusable packaging plastics, which then have to be perfectly recycled by the customers and then cleaned by waste managing units to make them suitable for the ReOil processes. In other words, it is not just the plastic industry which will have to adapt by investing in ReOil infrastructures, but rather the entire consumption-chain, which will have to be transformed.

Potential: creating alternatives for plastic dependent industries

The ReOil process will certainly not be an effective enough key-innovation to efficiently reduce the plastic waste already present in the environment today, as it is built to convert only well-recycled plastics and no old disposed-of-materials. The potential however may lie in creating a beneficial foundation for plastic dependent industries of the future, such as medical institutions and laboratories by reducing their fossil fuel dependence and greenhouse gas emissions.

As a matter of fact, a study in 2016 constructed by the Austrian Federal Environmental Agency about the process of waste plastic recycling concluded that substituting synthetic crude oil for fossil crude oil could result in a 45% reduction in greenhouse gas emissions together with a 20% lower requirement for energy input as well as a drastic reduction of fossil fuels needed in plastic production [6].

Plastic waste control starts at home

However, until methods like ReOil reach industrial-scale capacity and gain more public interest, the problem of plastic waste will have to be approached by every single person at home.

Considering, that the path of improving our recycling efficacy and reducing the amount of fossil-based plastic has already sparked interest in many different societal and economic groups, we may be up to a good start of transitioning to a circular plastics economy and the foundations for the path are currently being laid out. If we aim to avoid any further pollution of the environment with plastic waste from now on however, the initiative will have to be taken by the public, through conscious consumption and disposal of plastic and political action to innovate recycling systems. A circular plastics economy is not feasible if we solely rely on innovative recycling methods like ReOil but instead demands the innovation of the entire system. Once we establish a highly efficient plastic usage and recycling system, adding technical solutions like ReOil to the end of the loop may actually grant the perfect solution to close the gap and make the plastics industries sustainable.

SDG’s in context

Inarguably, plastic pollution is one of the most threatening global problems of the 21st century and will increase to become important in the future. While many technologies are being developed to fight plastic pollution, fossil based plastic production and plastic decomposition, the dimensions of the problem are still not easily estimated. Discoveries of plastic-decomposing bacteria have been stated, however this will most likely not solve the problem in the foreseeable future. The problem has simply already taken dimensions far too large. Many ecosystems are already suffering tremendously under the harm plastic waste causes them, and therefore it is crucial to propose solutions, which address the problem as soon as possible. Creating plastic, whether from recycled crude oil or fossil crude oil, may not seem like a step forward at all at first glance, however if we take into account, that by recycling waste plastic no further contribution to Garbage Patches is being done, this may definitely be a worthy innovation. It will support the Sustainable Development Goals in many different areas, such as

- 6 clean water and sanitation

- 9 industry, innovation and infrastructure

- 11 sustainable cities and communities

- 12 responsible consumption and production

- 14 life below water

- 15 life on land

- 17 partnerships for the goals

and therefore suggests a very promising alternative to current fossil fuel based plastics production.

Videolink: ReOil: getting Crude Oil back out of Plastic

Some interesting facts and data about plastic pollution:

https://ourworldindata.org/plastic-pollution

References:

[1] https://feature.undp.org/plastic-tidal-wave/

[2] https://www.weforum.org/agenda/2019/10/plastics-what-are-they-explainer/

[3] https://ourworldindata.org/grapher/surface-plastic-mass-by-ocean

[5] http://www.icfs2019.org/wp-content/uploads/2019/11/OMV-factsheet-ReOil-september-2018.pdf

[6]: https://energyindustryreview.com/oil-gas/there-and-back-again-turning-plastic-back-into-oil/

Media Attributions

- surface-plastic-mass-by-ocean

- Bildschirmfoto 2020-04-06 um 12.46.28